Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

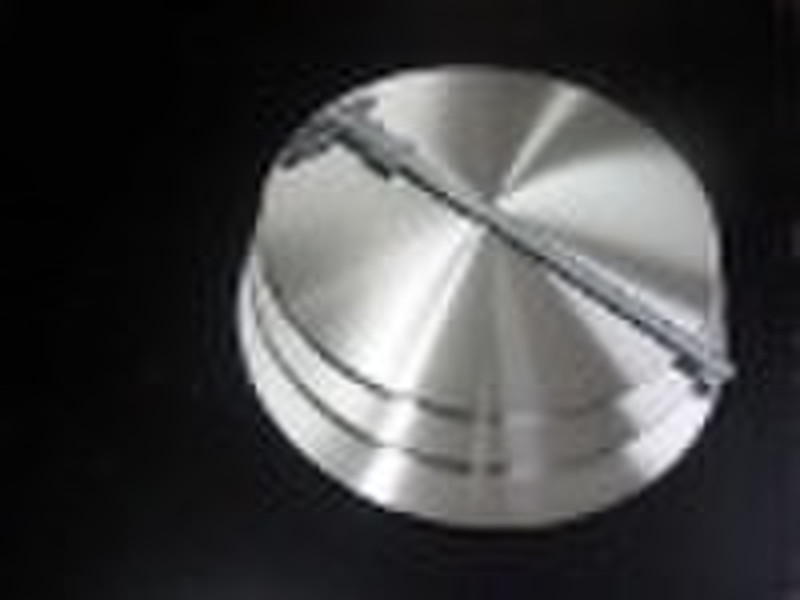

High-density Tungsten alloy for weight balance

Amy Yu

Contact person

Basic Information

| Place of Origin | Beijing China (Mainland) |

|---|---|

| Brand Name | AT&M |

ABOUT PRODUCTTungsten heavy Alloy have long been specified for control surface counterbalancesin aircraft and helicopters. Large mass in a small space isrequired to balance and stabilize control surfaces which must operateat high speeds. A savings in total aircraft weight can result from theuse of these materials because the small high density piece requiresless surrounding material to enclose it. In addition, the high strengthof the material permits the part to be located for the most efficientweight effect and therefore uses the minimum amount of material.Property: Tungsten content(wt%): 90-97 High density 16.0 18.5g/cm3 High strength 580 950Mpa Good plastic Good corrosion-resistant Good machining property High thermal conductivity Low coefficient of thermal expansion high mass absorption coefficient Application: Kinetic energy penetrators Counterweights in aircraft and ship applications Gyroscope rotors Flywheel rim Governors Radiation shielding Specifications: Maximum Size:φ550×1300mmABOUT PLANT Refractory metal and ceramics planthas been developing from Refractory Alloy Research Department of CISR(Central Iron & Steel Research Institute) founded in 1958. As one ofthe earliest unit engaged in refractory metal research and production inChina,over the past 50 years, more than 250 research projects have beendone and 58 great achievements have been made including 9 national inventions,40 metallurgy ministry awards and 21 national patents. Now weare at the top-level in refractory metal and ceramic material researching and producing within more than 300 sets of advanced production equipments and 20 sets of testing facilities. AT&M Refractory Plant is ISO9001:2000 certified.ABOUT EQUIPMENTS The main equipments include: Φ1250×2300mm cold and hot isostatic pressing achine; Tmax=2,400 high temperature sintering furnaces;large-scale vacuum sinteringfurnaces;Large infiltration furnaces for metal and metal ceramic composites;Tmax=2000 high temperature tensile strength tester;Ultrasonic crack detector; Laser thermal conductivity tester; laser powder particle size tester.ANNUAL CAPACITY The annual production capacity is more than 600 tons of tungsten heavy alloy products.

Payment term

Documents Against Payment

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: